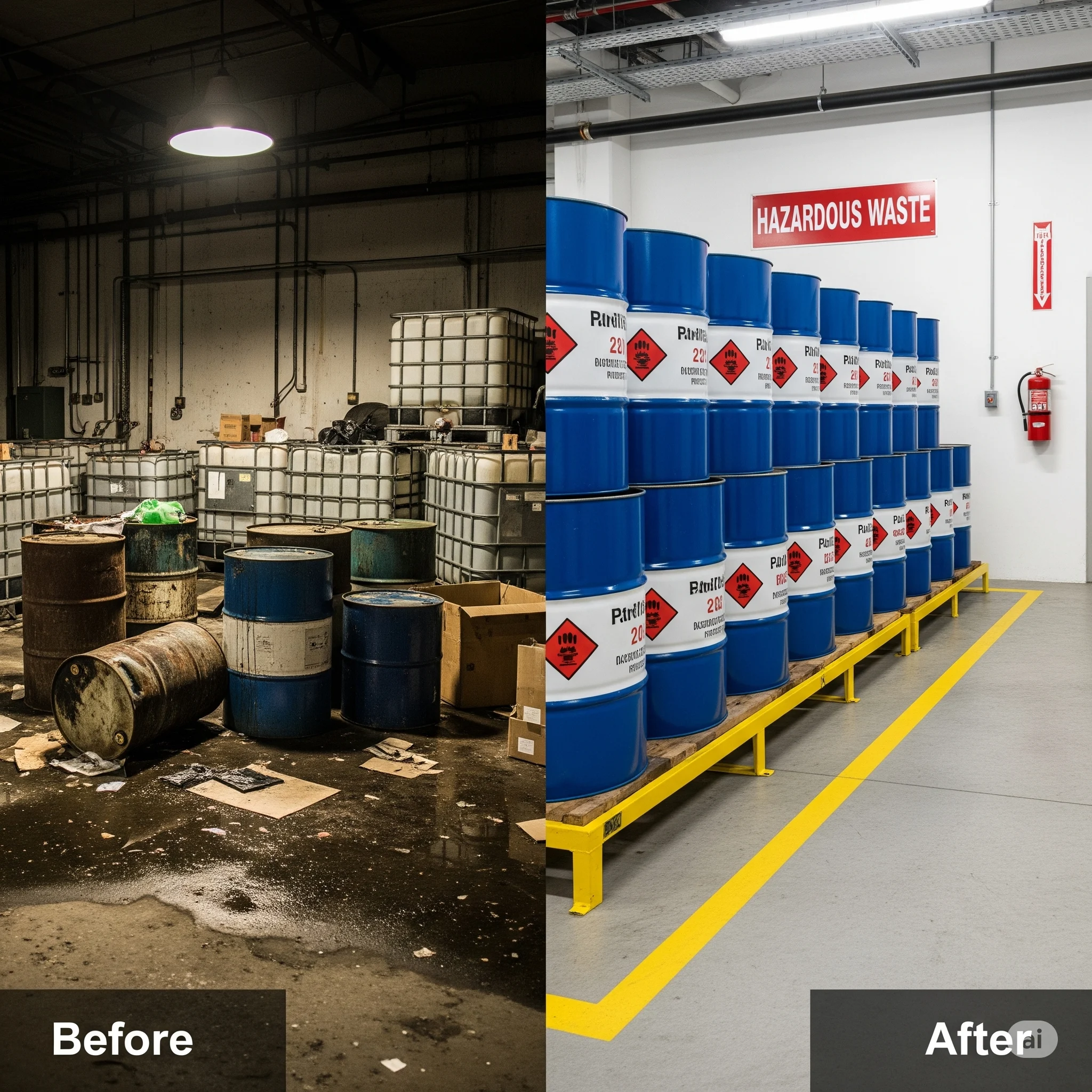

Compliant on-site storage is the foundation of a safe waste management program. However, even well-intentioned businesses can make simple errors that lead to safety risks and potential fines from the Department of Environment (DOE).

Are you making any of these common scheduled waste storage mistakes? Here’s how to identify and fix them.

Mistake #1: Improper or Missing Labels

One of the most frequent violations is incorrect labeling. A container with a missing generation date, an incorrect waste code, or no hazard symbol is a major compliance issue.

- The Fix: Implement a strict labeling protocol. Ensure every container is labeled the moment waste is first added. The label must clearly show the SW code, generation date, and your company’s details. Use durable, weatherproof labels that won’t fade or fall off.

Mistake #2: Mixing Incompatible Wastes

Storing different types of waste in the same container to save space is a dangerous mistake. Mixing incompatible chemicals can cause violent reactions, release toxic gases, or even start fires.

- The Fix: Never mix different waste streams. Dedicate separate, clearly labeled containers for each type of scheduled waste you generate. Train your staff on the importance of proper segregation to prevent accidents.

Mistake #3: Inadequate Spill Containment

Simply placing drums on a concrete floor is not enough. If a container leaks, the hazardous material can spread, contaminate your facility, and potentially enter the environment.

- The Fix: Your designated storage area must have a secondary containment system, such as a bund wall or spill pallets. This system must be made of an impermeable material and be large enough to hold at least 110% of the volume of the largest container in the area.

By avoiding these common scheduled waste storage mistakes, you can significantly improve the safety and compliance of your facility, protecting your employees, the environment, and your business from liability.